Electrical Inspections

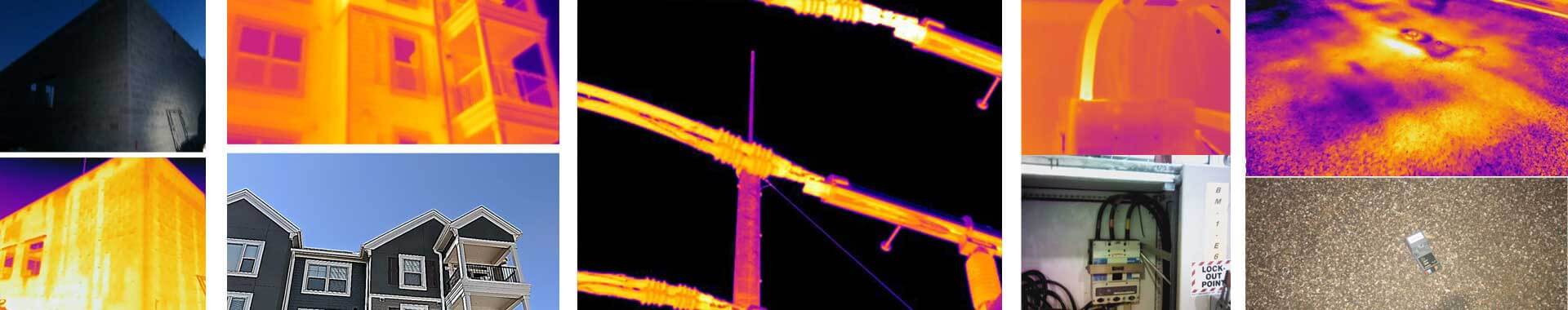

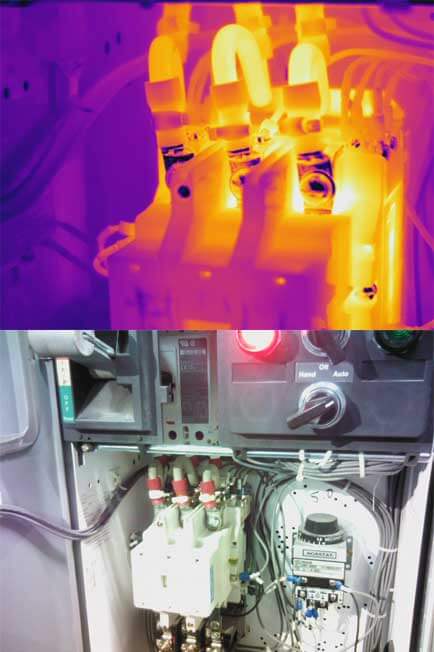

Infrared thermography is used to perform Preventative and Predictive Maintenance inspections on electrical equipment. Excess resistance on electrical apparatuses indicates electrical faults such as loose connections, overloaded or imbalanced circuits, faulty breakers, damaged switches, faulty fuses and a wide range of other unwanted electrical conditions. Before an electrical component burns up, it heats up. Thermography is used to see the excess heat (resistance) so that problems can be found and maintenance personnel can act to correct the problem before the component fails. Without this maintenance, a facility could experience safety hazards, production downtime, and damaged equipment. With our extensive network of qualified partners, we offer nationwide services.

You may also ask your insurance provider if they offer discounts based on infrared inspections. If they do offer discounts, the insurance provider will usually require a 3rd-party (independent) infrared inspector to be at least Level 2 certified. All Pinnacle Infrared inspectors are Level 2 certified or higher. There may also be requirements for a high-resolution and/or high temperature detector. Pinnacle Infrared’s equipment is capable of meeting all insurance (and your processes’) requirements.

All thermal, visual, and ultrasound problems will be fully documented and recorded. Upon completion of the inspection, the infrared technician will provide an out brief to discuss any severe problems and answer questions. A detailed report will then be processed and available within seven to ten business days. For expediency, a PDF report will be emailed and, upon request, a hard copy will be available.

We provide an easy-to-understand and comprehensive report that will comply with any insurance requirement. Your report will come with detailed imagery and description for each problem. Each finding will include both a high resolution infrared image along with a visual image and other pertinent information such as loading conditions, temperature rise, max temperature, date, possible cause and repair suggestions. Each problem is assigned a priority rating based on severity and the equipment’s operational importance to the facility.

What Electrical Distribution Equipment Should Be Checked?

- Utility substations, transformers and feed poles

- Main incoming services, plant main knives, capacitor banks, etc

- Main switchboards and disconnects

- Main distribution panels and main disconnects

- Uninterruptible power supplies

- Generator controls and transfer switches

- Main I-Line panels

- Lighting and receptacle panels

- Disconnects and combination starters

- Service disconnects for motors

- Machine control panels

Typical Clients

- Facility Engineers

- Facility Maintenance Mangers

- Property Managers

- Building Owners

- Electrical Engineers

- Electricians

- Architects

- HVAC Contractors

- General Contractors

Types of Facilities

- Manufacturing Facilities

- Industrial Facilities

- Office Buildings

- Universities

- Hospitals

- Hotels

- Retail Malls

- Shopping Centers

- Schools