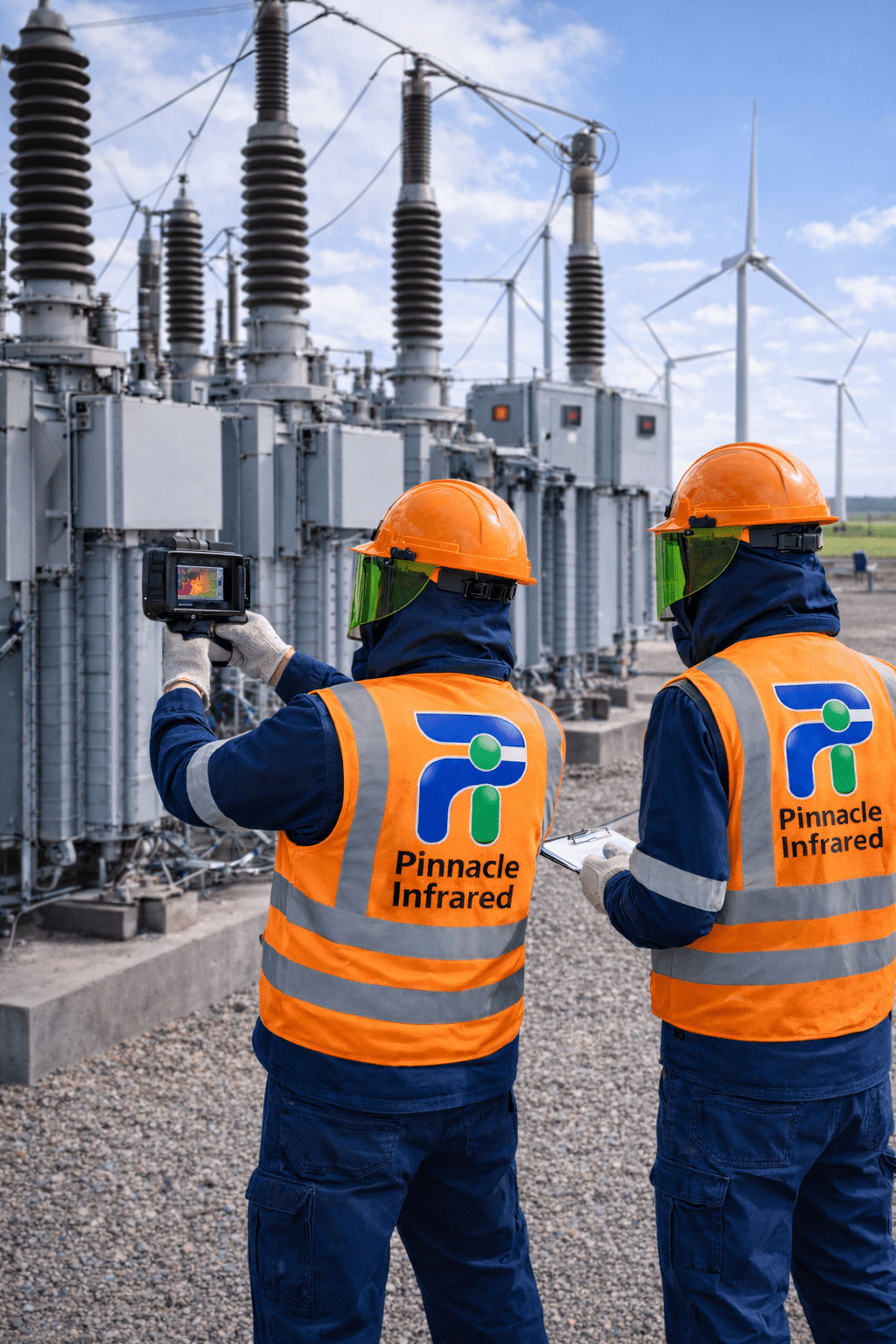

Our services are particularly beneficial for industries focused on wind energy, helping to optimize maintenance strategies and enhance system performance.

Unlock the Power of Infrared Thermography for Predictive Maintenance in Wind Energy

At Pinnacle Infrared, we harness the power of infrared thermography to provide predictive maintenance services that go beyond traditional methods. Our advanced technology allows us to detect potential issues before they escalate, saving you time, money, and resources. With our comprehensive approach, you can ensure the reliability and longevity of your electrical systems.

Early Fault Detection

Enhanced Safety Measures

Cost-Effective Solutions

Unlock the Power of Predictive Maintenance

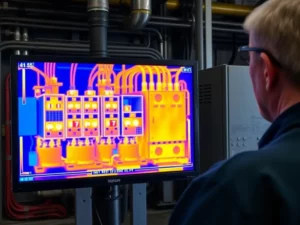

Infrared thermography is a game-changer for electrical maintenance. By detecting heat patterns invisible to the naked eye, we identify potential problems before they lead to costly downtime or safety hazards. Our predictive maintenance services empower you to optimize performance, extend equipment lifespan, and ensure a safer working environment.

- Reduce Downtime: Identify and address issues before they cause equipment failure.

- Improve Safety: Detect potential fire hazards and electrical faults.

- Extend Equipment Life: Optimize performance and prevent premature wear.

- Lower Energy Costs: Identify energy waste and improve efficiency.

- Increase Productivity: Minimize disruptions and maximize uptime.

- Ensure Compliance: Meet regulatory requirements and industry standards.

Early Detection of Wind Turbine Issues

Enhanced Solar Panel Efficiency

Improved Safety and Reliability

Reduced Maintenance Costs

Wind Farm Electrical Inspections

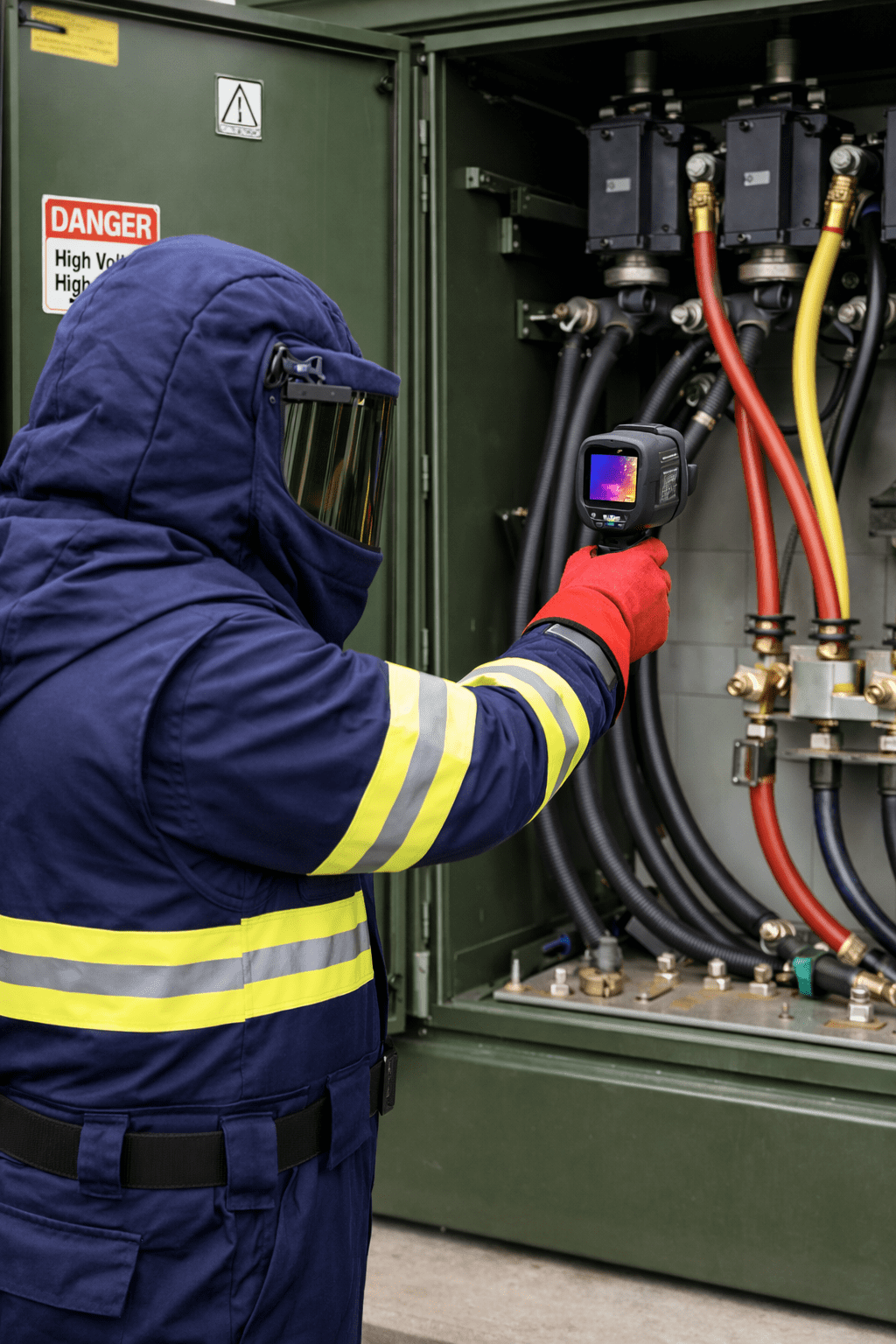

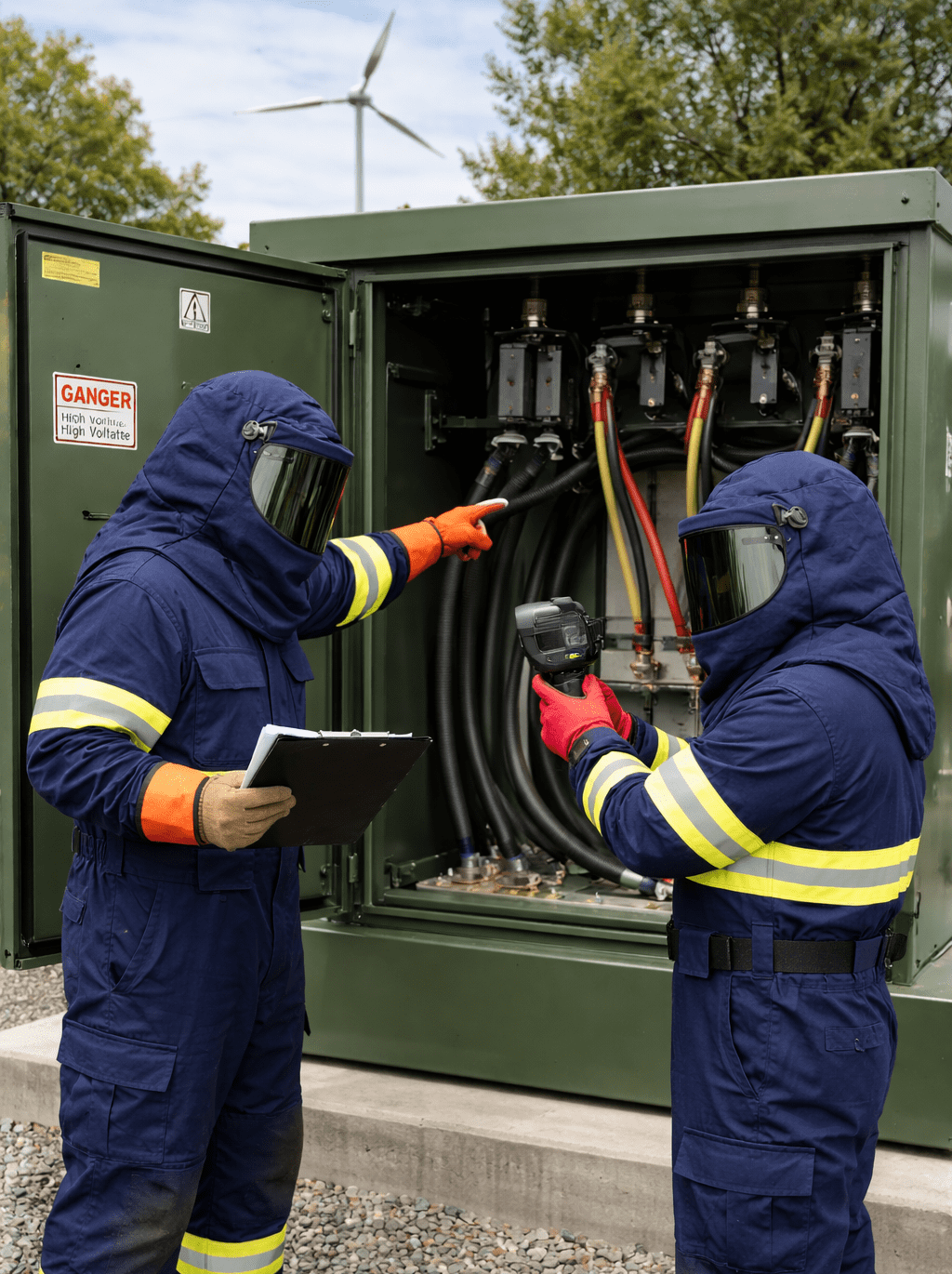

Our technicians utilize advanced infrared and ultrasonic tools to safely inspect transformers and electrical components from a distance, ensuring optimal performance and safety.

Our services are particularly beneficial for industries focused on wind energy, where reliability, safety, and cost control are critical. By integrating advanced inspection methods such as infrared thermography, ultrasonic testing, and predictive maintenance techniques, we help operators identify developing issues before they lead to unplanned outages or costly repairs. Early detection of electrical hot spots, mechanical wear, moisture intrusion, or compressed-air leaks allows maintenance teams to plan corrective actions during scheduled service intervals rather than reacting to emergency failures.

This proactive approach not only extends the life of critical components—such as transformers, switchgear, cables, and turbine systems—but also improves overall system efficiency and energy output. In addition, it supports safety compliance, reduces downtime, and provides detailed reporting that helps asset managers make informed, data-driven decisions. The result is a more reliable wind farm, optimized maintenance budgets, and improved long-term performance.

Our services are particularly beneficial for industries focused on wind energy, where reliability, safety, and cost control are critical to maintaining consistent power generation and protecting long-term asset value. Wind farms operate in demanding environments and rely on complex electrical and mechanical systems that must function continuously under varying loads, weather conditions, and operational stresses. Even minor electrical or mechanical deficiencies can gradually develop into major failures, resulting in unplanned downtime, costly emergency repairs, and potential safety hazards. By implementing advanced inspection technologies and predictive maintenance strategies, our services help wind-energy operators stay ahead of these issues and maintain peak performance across their assets.

One of the most effective tools in this approach is infrared thermography. This non-contact technology allows technicians to safely evaluate energized electrical components and mechanical systems by detecting abnormal heat patterns. Elevated temperatures often indicate problems such as loose or corroded connections, overloaded circuits, insulation breakdown, or internal component degradation. In wind-farm environments, thermographic inspections are commonly used on pad-mounted transformers, switchgear, cable terminations, control panels, inverters, and other critical infrastructure. By identifying these issues early, operators can schedule corrective maintenance during planned service intervals, rather than responding to unexpected equipment failures.

Ultrasonic inspection is another valuable component of a predictive maintenance program for wind-energy facilities. This technology is used to detect compressed-air or gas leaks, electrical arcing, tracking, and corona discharge—issues that may not be visible or detectable through traditional inspection methods. In electrical systems, ultrasonic tools can identify high-frequency sound emissions caused by insulation breakdown or partial discharge activity. Detecting these problems early helps prevent catastrophic electrical failures and reduces the risk of fire or extended outages. For facilities that use compressed-air systems, ultrasonic leak detection also helps eliminate energy losses and reduce unnecessary operating costs.

Together, infrared and ultrasonic inspections provide a comprehensive view of asset condition without interrupting operations. Because these methods are non-destructive and performed while equipment is energized and in service, they offer a practical way to monitor system health under real operating conditions. This allows maintenance teams to prioritize repairs based on severity and risk, rather than relying solely on time-based maintenance schedules. As a result, resources are allocated more efficiently, and unnecessary maintenance tasks can be reduced.

Predictive maintenance strategies built around these technologies play a crucial role in improving wind-farm reliability. Instead of waiting for components to fail, predictive maintenance focuses on identifying early warning signs and addressing them before they escalate. This approach reduces unplanned downtime, improves energy production, and extends the service life of critical equipment. For example, a loose electrical connection detected during a thermographic inspection can be tightened or repaired during a scheduled maintenance window, preventing a potential transformer failure or circuit interruption. Similarly, identifying partial discharge in switchgear through ultrasonic testing can lead to corrective action that prevents costly insulation breakdown.

Another significant advantage of these services is improved safety. Wind-energy facilities involve high-voltage equipment, elevated structures, and remote locations, all of which present unique risks to personnel. Predictive inspection methods allow technicians to assess equipment from a safe distance, minimizing the need for intrusive or hazardous procedures. By identifying problems before they become dangerous, these services help reduce the likelihood of arc-flash incidents, electrical fires, and other safety-related events. This proactive approach supports compliance with industry safety standards and helps protect both workers and equipment.

In addition to improving reliability and safety, our services contribute to better financial performance. Unplanned outages can result in lost energy production, emergency repair costs, and potential contractual penalties. By reducing the frequency and severity of unexpected failures, predictive maintenance programs help stabilize operating budgets and improve return on investment. Energy losses caused by electrical inefficiencies or compressed-air leaks can also be minimized, further enhancing overall system efficiency.

Comprehensive reporting is another key benefit of our services. After each inspection, detailed reports provide clear documentation of equipment conditions, identified anomalies, and recommended corrective actions. These reports often include thermal images, ultrasonic data, and visual documentation, along with severity classifications and maintenance priorities. This information enables asset managers and maintenance teams to make informed, data-driven decisions. Over time, historical inspection data can be used to track trends, evaluate equipment performance, and refine maintenance strategies for even greater efficiency.

Wind-farm operators also benefit from the flexibility and scalability of predictive inspection programs. Whether managing a small group of turbines or a large, multi-site wind-energy portfolio, these services can be tailored to meet specific operational needs. Inspections can be scheduled annually, semi-annually, or as part of a continuous monitoring strategy, depending on the age of equipment, operating conditions, and risk tolerance. This adaptability ensures that maintenance programs remain aligned with both technical requirements and budgetary goals.

Furthermore, predictive maintenance supports sustainability and environmental responsibility. By keeping equipment operating efficiently, wind-energy facilities can maximize power output and reduce waste associated with premature component replacement or emergency repairs. Preventing failures also reduces the likelihood of environmental hazards, such as oil leaks from transformers or fires caused by electrical faults. In this way, proactive maintenance not only protects equipment but also helps preserve the surrounding environment and maintain public trust in renewable-energy operations.

Ultimately, our services provide wind-energy operators with the tools and insights needed to maintain reliable, efficient, and safe power-generation systems. By combining advanced inspection technologies, predictive maintenance strategies, and comprehensive reporting, we help identify potential issues before they become major problems. This proactive approach extends equipment life, improves energy production, enhances safety compliance, and reduces overall operating costs.

As the demand for renewable energy continues to grow, the importance of reliable wind-farm performance becomes even more critical. Predictive maintenance and advanced inspection services offer a practical, cost-effective way to meet these challenges while supporting long-term operational success. Through early detection, informed decision-making, and strategic maintenance planning, wind-energy operators can achieve greater system performance, improved asset longevity, and stronger financial outcomes.