Table of Contents

Infrared Electrical Inspections

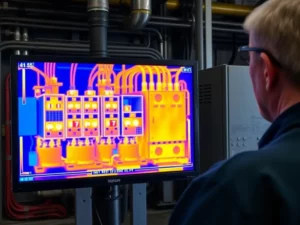

Infrared electrical inspections, also known as thermographic inspections, have emerged as a pivotal technique across various industries, providing critical data that enhances safety, efficiency, and reliability. By utilizing infrared technology to visualize heat patterns, professionals can identify potential issues that may not be visible to the naked eye. This innovative approach not only aids in preventive maintenance but also plays a crucial role in ensuring workplace safety and operational efficiency.

Infrared inspections are employed in numerous fields, including electrical, mechanical, building, and aerospace sectors. Their applications vary from identifying electrical faults to assessing building insulation. As technology advances, the scope of infrared inspections continues to expand, offering vital insights that help organizations mitigate risks and maintain high operational standards. Order your infrared services today!

Safety Benefits of Infrared Inspections

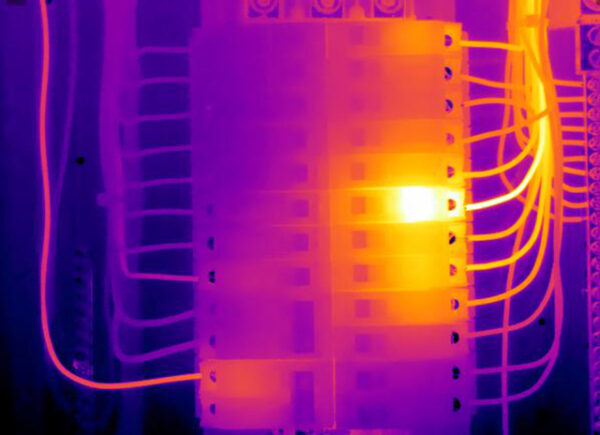

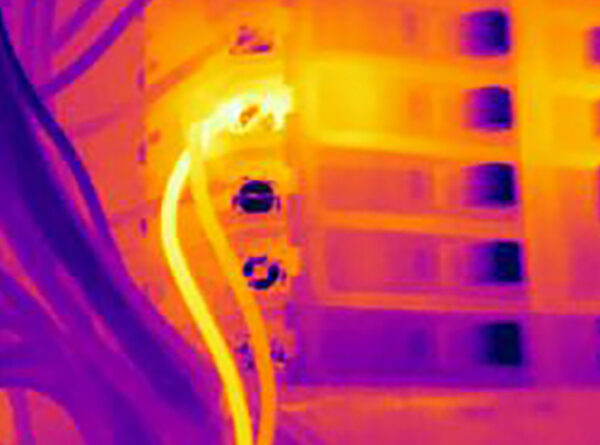

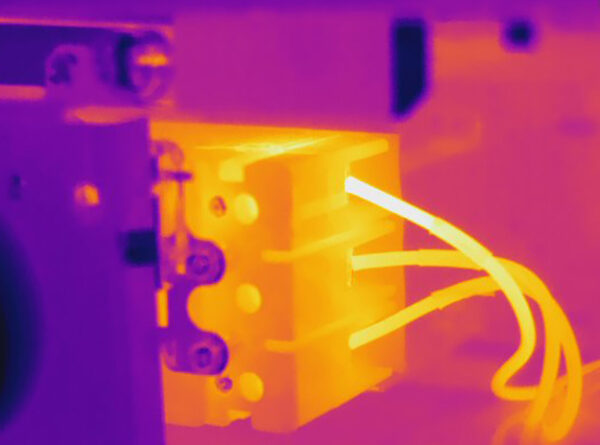

One of the most significant safety benefits of infrared inspections is their ability to identify electrical hazards before they escalate into serious incidents. Overheating connections or components can lead to equipment failure or, in worst-case scenarios, fires. Infrared cameras can detect excess heat emanating from electrical systems, allowing for timely interventions. By recognizing these anomalies, companies can address issues proactively, enhancing overall safety.

Moreover, infrared electrical inspections can be performed without interrupting operations, which is a considerable advantage. This non-invasive approach not only protects equipment but also ensures that personnel are less exposed to potential dangers associated with faulty electrical systems.

Reducing Fire Risks

The potential for fire due to electrical failures or overheating equipment is a prevailing concern in many industries. Infrared inspections play a crucial role in mitigating this risk. By regularly monitoring equipment and electrical systems, organizations can identify hot spots and other precursors to fire hazards. This proactive approach significantly reduces the likelihood of fire-related incidents, thereby protecting assets and ensuring the safety of personnel.

Implementing a systematic infrared inspection process can lead to improved fire safety protocols, as organizations can formulate strategies based on real-time data. This not only instills confidence in employees but also ensures compliance with relevant safety regulations.

Enhancing Workplace Safety

Workplace safety is paramount, and infrared inspections contribute significantly to creating a safer environment. By detecting potential hazards early, these inspections help organizations take corrective actions before accidents occur. For example, mechanical systems that overheat can lead to machinery failures, posing risks to operators and bystanders. Regular infrared inspections help in maintaining equipment health and ensuring that safety protocols are followed.

Furthermore, by investing in infrared inspections, organizations demonstrate their commitment to employee safety. This initiative can enhance workplace morale, as employees feel valued and protected within their work environment.

Efficiency Improvements Through Infrared Inspections

Efficiency is a critical factor in any organization, and infrared electrical inspections can significantly streamline operations. By identifying inefficiencies in equipment or processes, businesses can make informed decisions to optimize their operations. For instance, if a particular machine is consistently overheating, it may indicate that it requires maintenance or an operational change. Addressing such issues leads to smoother workflows and increased productivity.

Moreover, infrared technology allows for quick assessments of multiple systems in a short amount of time. This efficiency means that companies can allocate their resources more effectively, ensuring that critical components are prioritized.

Minimizing Downtime

Downtime is costly for businesses, both in terms of lost revenue and decreased productivity. infrared electrical inspections serve as a preventive measure, allowing organizations to identify and rectify issues before they necessitate extensive repairs or lead to equipment failure. By minimizing unexpected downtimes, businesses can maintain continuous operations and ensure that their manufacturing or service processes run smoothly.

Additionally, having a structured infrared inspection schedule helps organizations plan maintenance activities more effectively. This proactive approach allows for better allocation of resources, minimizing interruptions that would otherwise impact productivity.

Optimizing Resource Allocation

Effective resource management is crucial for any organization, and infrared inspections play a vital role in this regard. By providing detailed insights into the condition of equipment, these inspections allow businesses to prioritize their maintenance efforts and allocate resources where they are most needed. This means that financial and human resources can be directed towards high-risk areas, ensuring that investments yield maximum returns.

Furthermore, accurate data from infrared inspections can help in budgeting for future maintenance and upgrades, providing a clearer picture of potential costs and resource requirements. In this way, organizations can plan with foresight rather than reactively addressing issues as they arise.

How Infrared Inspections Impact Insurance Premiums

The correlation between infrared inspections and insurance premiums is evident; those who regularly conduct these inspections often find themselves with lower premiums. Insurance providers favor organizations that take a proactive approach to risk management, as they are less likely to file claims. By investing in an infrared inspection program, businesses not only enhance their safety measures but also potentially save significantly on their insurance costs.

This financial advantage can be particularly attractive for small to medium-sized enterprises, where every dollar counts. Hence, integrating infrared inspections into standard operating procedures can be viewed as a strategic investment that yields both safety and financial returns.