Understanding the Importance of Infrared Inspections

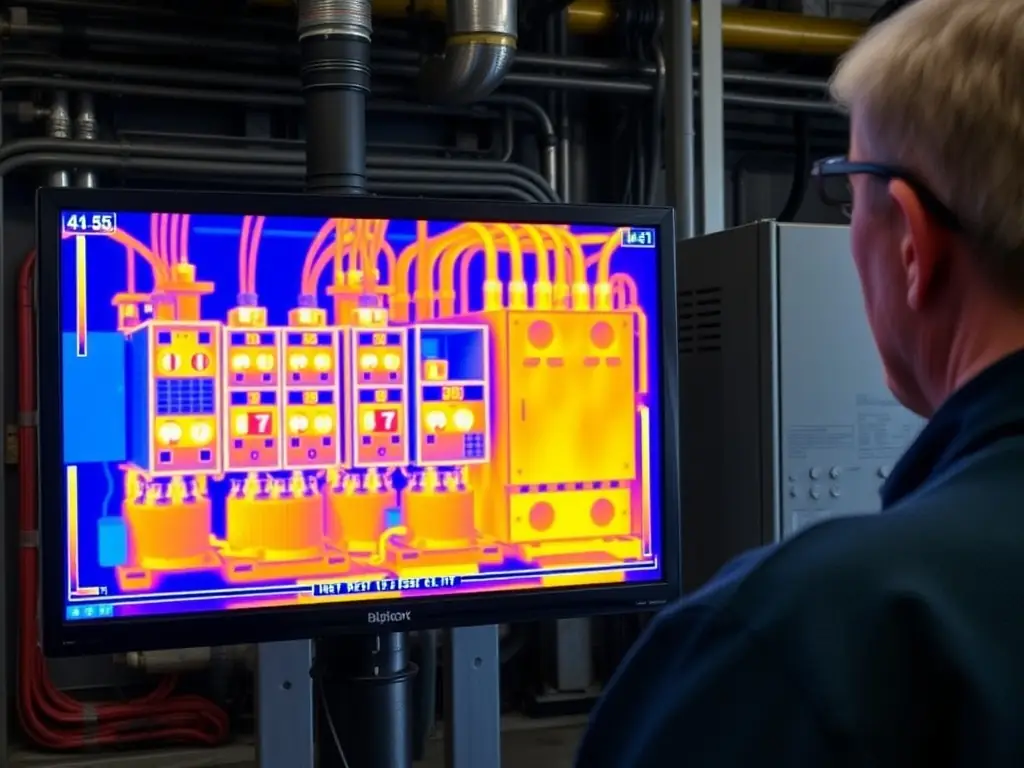

Infrared Inspection in Action

Why Infrared Inspections Matter

Infrared inspections are crucial for identifying potential electrical failures before they escalate. Our certified thermographers utilize cutting-edge technology to ensure your systems operate safely and efficiently, minimizing downtime and costly repairs.

We have served over 1000 clients nationwide, establishing ourselves as a trusted partner in electrical maintenance.

Explore Our Comprehensive Infrared Solutions

Electrical Panel Inspections

Infrared Roof Surveys

Wind Farm Evaluations

Infrared inspections play a vital role in the maintenance of electrical systems, providing a non-invasive method to detect potential issues before they escalate. By utilizing thermal imaging technology, professionals can identify hotspots and anomalies that may indicate electrical failures. This proactive approach not only enhances safety but also extends the lifespan of electrical equipment, ultimately saving businesses time and money. Regular infrared inspections are essential for any organization that relies on electrical systems for their operations.

At Pinnacle Infrared, our team of certified thermographers is trained to conduct thorough infrared inspections tailored to the specific needs of each client. We understand that every facility is unique, and our assessments are designed to provide accurate and reliable data. By identifying potential problems early, we help our clients avoid costly downtime and ensure their operations run smoothly. Our commitment to precision and safety sets us apart in the industry.

In addition to electrical inspections, our infrared technology can be applied to various areas, including roof surveys and building envelope evaluations. This versatility allows us to offer comprehensive solutions that address multiple aspects of facility maintenance. By choosing Pinnacle Infrared, clients can rest assured that they are receiving the highest level of service and expertise in infrared inspections.